STAMPING AND MOULDING TECHNOLOGY

For the high-precision and efficient production of moulded metal parts from strip material, stamping and bending are the right manufacturing technologies, especially for medium and large series.

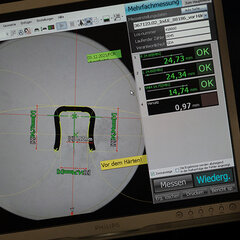

Efficiency and precision

Especially for complex parts, these production processes are characterised by high precision, efficiency and individual design options. Our experts select the appropriate processes based on the desired quantity, the materials used, the complexity of the parts and the intended application scenario and accompany the order from the initial enquiry through to delivery.

Stamping and bending

When manufacturing complex metal parts, several stamping and bending steps that must be carried out one after the other in a clearly defined sequence are often required. Thanks to extensive automation possibilities and the combination with other production processes, high cost efficiency and production speed can be achieved in stamping and bending, especially for large quantities.

To ensure that each of these processes is always at the cutting edge of technology, our employees have access to modern machinery with reliable maintenance and servicing. This allows all production processes to be used flexibly, fulfilling even complex orders with seamless work processes and in highest quality.