SPRING TECHNOLOGIES

Insights into spring production

Depending on the part design, the requirements of the component and the choice of material, we use a range of manufacturing techniques and processes for the production of compression, tension or torsion springs, bent wire parts or assemblies with spring components.

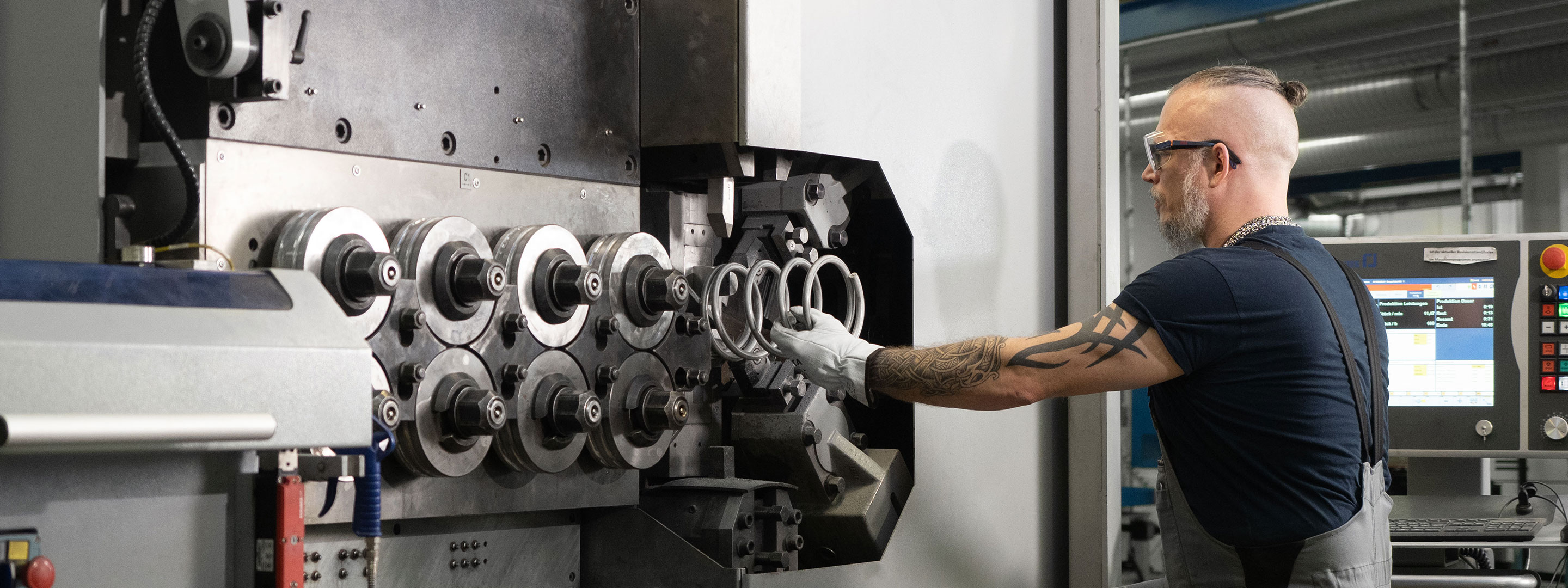

An extensive range of state-of-the-art machinery is available to our experienced production staff. Many years of expertise and technological development guarantee the highest quality for our customers.

Coiling

Similar to winding, coiling a wire into a spring is also a cold forming process. Here, however, the wire is wound around a mandrel to shape it into the desired form. Coiling is a manufacturing technique that is mainly used to produce compression, tension and torsion springs. The particular process used for production depends on the desired application scenario and the related material requirements.

Wire bending

Bending allows bent wire parts to be manufactured reproducibly in almost any conceivable shape and design. The process enables the precise, efficient and cost-effective production of components in customised designs and with different materials.

Hot and cold setting

During hot and cold setting, springs are individually prepared for their later use by deliberately pushing them to and beyond their load limits. This ensures during the production stage that there is no loss of length or strength later on due to prolonged use. Depending on the intended application and customer requirements, various work steps are carried out on different systems.